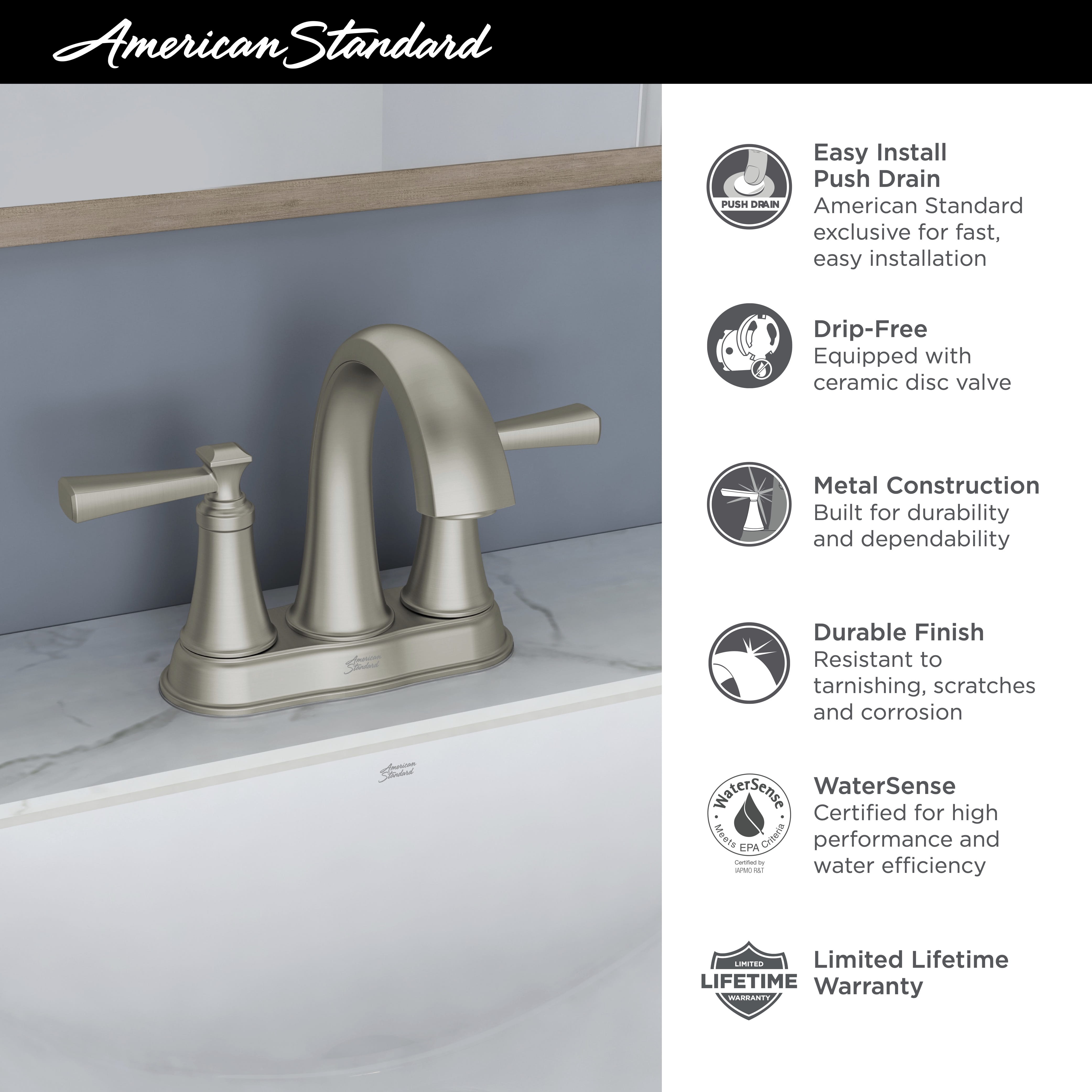

Understanding the American Standard Two-Handle Bathroom Faucet

American Standard two-handle bathroom faucets are a common fixture in many homes, offering a reliable and stylish way to control water flow and temperature. Understanding the components and operation of these faucets can be helpful for troubleshooting issues or even upgrading them.

Components of an American Standard Two-Handle Bathroom Faucet

These faucets typically consist of several key components that work together to provide water flow and temperature control.

- Spout: This is the part of the faucet that delivers water. It is usually made of metal, such as brass, and may have a variety of finishes, such as chrome, nickel, or brushed nickel.

- Handles: Two handles, one for hot water and one for cold, control the flow and temperature of the water. These handles are usually made of metal or plastic and are connected to the cartridge.

- Cartridge: The cartridge is the heart of the faucet, controlling water flow and temperature. It is located inside the faucet body and is typically made of ceramic or metal.

- Faucet Body: The faucet body is the main structure of the faucet, housing the cartridge and other components. It is usually made of brass or other durable materials.

- Aerator: The aerator is a small device located at the end of the spout that mixes air with the water, creating a smooth and even flow.

- Supply Lines: These lines connect the faucet to the hot and cold water supply pipes. They are usually made of braided stainless steel or flexible plastic.

Cartridge Types

American Standard two-handle bathroom faucets typically use one of two types of cartridges: ceramic disc cartridges or ball cartridges.

Ceramic Disc Cartridges

Ceramic disc cartridges are becoming increasingly popular due to their durability and smooth operation. These cartridges use two ceramic discs with precisely machined grooves to control water flow. The discs are pressed together to regulate the flow, and a rubber seal prevents leaks.

Ball Cartridges

Ball cartridges are a more traditional type of cartridge. They use a ball-shaped valve with grooves to control water flow. The ball is rotated by the handle, and the grooves align with the inlet and outlet ports to allow water to flow. Ball cartridges are known for their simplicity and affordability, but they may not be as durable as ceramic disc cartridges.

Materials Used in American Standard Two-Handle Bathroom Faucets

American Standard two-handle bathroom faucets are typically made of durable materials to ensure longevity and performance.

- Brass: Brass is a common material used for the faucet body, spout, and handles. It is known for its strength, durability, and resistance to corrosion.

- Chrome: Chrome is a popular finish for bathroom faucets, providing a sleek and shiny appearance. It is also highly resistant to scratches and corrosion.

- Ceramic: Ceramic is used in ceramic disc cartridges, providing a smooth and precise control of water flow.

- Plastic: Some components, such as the handle knobs, may be made of plastic for durability and affordability.

Common Problems and Troubleshooting

American Standard two-handle bathroom faucets are known for their reliability, but like any plumbing fixture, they can encounter problems over time. Understanding common issues and how to troubleshoot them can save you time, money, and frustration.

Leaking Faucet

Diagnosing a leaking faucet is crucial for identifying the source of the problem. Here’s how to pinpoint the cause:

- Leaking from the spout: This usually indicates a worn-out O-ring or a loose cartridge in the faucet. Replacing the O-ring or cartridge can resolve the issue.

- Leaking from the handle: A leaking handle often points to a worn-out stem seal or a loose packing nut. Replacing the stem seal or tightening the packing nut can stop the leak.

- Leaking from the base of the faucet: A leak at the base suggests a problem with the faucet’s mounting ring or a loose connection to the water supply line. Tightening the mounting ring or replacing the supply lines can address this issue.

Low Water Pressure or Weak Stream

Low water pressure or a weak stream can be caused by various factors:

- Clogged aerator: The aerator, located at the end of the spout, mixes air with water to create a smooth flow. A clogged aerator can restrict water flow. Cleaning or replacing the aerator can solve this problem.

- Mineral buildup: Mineral deposits from hard water can accumulate in the faucet’s internal components, restricting water flow. Descaling the faucet with a vinegar solution can remove these deposits.

- Restricted water supply: Low water pressure in your home’s plumbing system can affect the faucet’s performance. Checking the main water valve and any other plumbing fixtures for similar issues can help diagnose the problem.

Faucet Won’t Turn On

If your faucet won’t turn on, the issue could be related to:

- Clogged cartridge: The cartridge is the main control valve in the faucet. If it’s clogged, it can prevent water flow. Replacing the cartridge can resolve this issue.

- Broken handle: A broken or damaged handle can prevent the cartridge from engaging properly. Replacing the handle or repairing it can fix the problem.

- Closed shut-off valves: The shut-off valves beneath the sink control the water flow to the faucet. Ensure they are fully open to allow water to flow.

Repairing the Faucet: American Standard Two Handle Bathroom Faucet Repair

Now that you’ve identified the issue with your American Standard two-handle bathroom faucet, it’s time to get your hands dirty and fix it. This section will guide you through the most common repair procedures, from replacing the cartridge to adjusting the handles and cleaning the components.

Replacing the Faucet Cartridge

The faucet cartridge is the heart of your two-handle bathroom faucet, controlling water flow and temperature. Replacing a worn-out cartridge is a common repair, and it’s often a straightforward process. Here’s how to do it:

- Turn off the water supply. Locate the shut-off valves for your bathroom sink, usually under the sink or on the wall. Turn the valves clockwise to shut off the water supply completely.

- Remove the faucet handles. Most two-handle faucets have a set screw on the handle that needs to be loosened with a small Allen wrench. Once the set screw is loose, the handle should pull off easily.

- Remove the faucet escutcheon. The escutcheon is the decorative plate that covers the faucet stem. You may need to pry it off gently with a flat-head screwdriver.

- Remove the old cartridge. The cartridge is usually held in place by a retaining nut. Use a wrench to loosen and remove the nut, and then pull out the old cartridge.

- Install the new cartridge. Insert the new cartridge into the faucet body, making sure it’s seated properly. Tighten the retaining nut, but don’t overtighten it.

- Reassemble the faucet. Replace the escutcheon, handles, and set screws.

- Turn the water supply back on. Slowly open the shut-off valves, checking for any leaks.

Adjusting the Faucet Handles

If your faucet handles are loose or don’t control the water flow and temperature properly, you can adjust them to restore proper function.

- Tighten the handle set screws. If the handles are loose, simply tighten the set screws with an Allen wrench.

- Adjust the handle stems. Some faucets have adjustable stems that can be used to fine-tune the water flow and temperature. To adjust the stems, you’ll need to remove the handles and access the stems using a wrench.

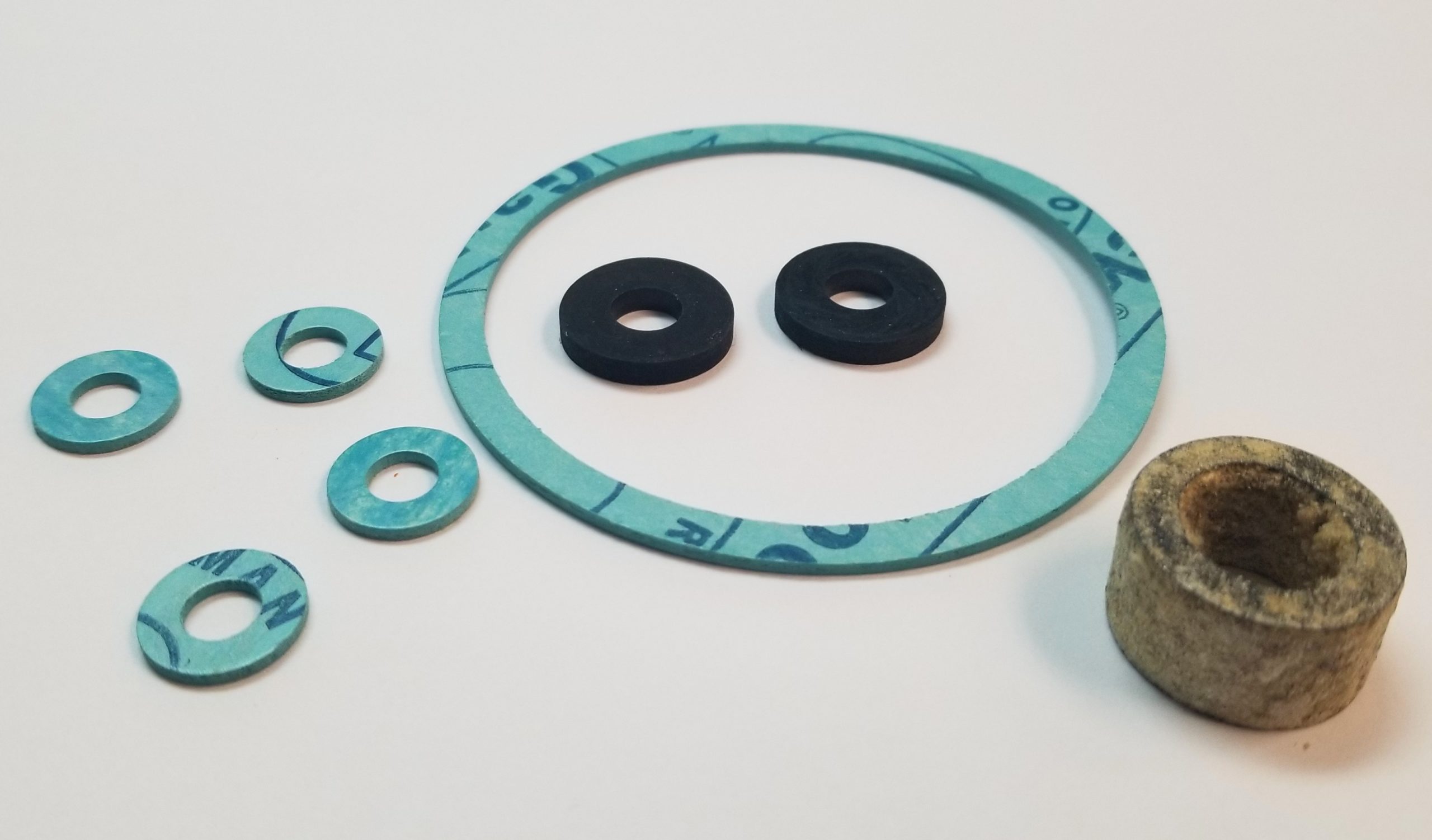

Replacing Worn-Out O-rings and Washers

O-rings and washers are small rubber or plastic components that help prevent leaks in your faucet. Over time, these components can wear out and need to be replaced.

- Identify the worn-out components. Look for cracked, torn, or flattened O-rings and washers.

- Remove the old components. Carefully remove the old O-rings and washers using a small screwdriver or pliers.

- Install the new components. Place the new O-rings and washers in their proper locations, making sure they are properly seated.

Cleaning and Lubricating the Faucet Components

Regular cleaning and lubrication can help keep your faucet running smoothly. Here’s how to do it:

- Remove the faucet components. Disassemble the faucet as described in the previous steps.

- Clean the components. Use a mild cleaner and a soft cloth to clean the faucet components. Avoid harsh chemicals that could damage the finish.

- Lubricate the components. Apply a small amount of silicone grease to the O-rings, washers, and other moving parts.

- Reassemble the faucet. Reassemble the faucet and turn the water supply back on.

Maintenance and Prevention

You’ve tackled the repairs, now let’s keep your American Standard two-handle bathroom faucet in tip-top shape. Regular maintenance can prevent future problems and extend the life of your faucet.

Preventing Mineral Buildup and Corrosion

Mineral buildup and corrosion are common culprits for faucet issues. Hard water, containing high mineral content, can leave deposits on the faucet’s surfaces and internal components, hindering its performance. To combat this:

- Regular Cleaning: Wipe down the faucet with a soft cloth and mild soap solution after each use. This removes surface grime and prevents mineral buildup.

- Descaling: For stubborn mineral deposits, use a descaling solution specifically designed for faucets. Follow the manufacturer’s instructions carefully.

- Water Softener: Consider installing a water softener if you have hard water. This reduces mineral content in your water, minimizing buildup on your faucet.

Using the Correct Cleaning Agents

Using the right cleaning agents is crucial for maintaining your faucet’s finish and preventing damage.

- Avoid Abrasives: Harsh abrasives like steel wool or scouring powders can scratch the faucet’s surface, leading to corrosion.

- Gentle Cleaners: Opt for mild soap, vinegar, or a faucet-specific cleaner. These effectively remove dirt and grime without damaging the finish.

- Avoid Bleach: Bleach can damage the faucet’s finish, especially chrome. Use alternative cleaning solutions for stubborn stains.

Storing and Handling Faucet Parts, American standard two handle bathroom faucet repair

Proper storage and handling of faucet parts is essential, especially when replacing or repairing components.

- Keep Parts Organized: Store disassembled parts in a clean, dry container to prevent damage or loss.

- Label Parts: Label each part for easy identification during reassembly.

- Avoid Over-Tightening: When reassembling the faucet, avoid over-tightening parts, as this can damage threads and lead to leaks.